Interview: Whitebirk's Steve Allen – Trump’s tariffs don’t bother us

Tue 6th May 2025 by Tim Wallace

Interview: Whitebirk's Steve Allen – Trump’s tariffs don’t bother us

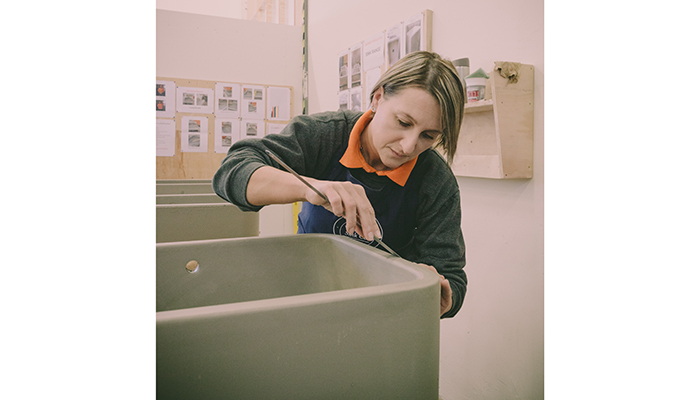

With a growing focus on the US market, the Whitebirk Sink Company – part of Darwen Terracotta – is enjoying great success under the guidance of industry veteran Steve Allen. Tim Wallace hears the full story.

You might consider this a bad time to be exporting kitchen and bathroom products to the US, but Steve Allen (pictured above left, with business partner Jon Wilson, right) takes a very different view. While other suppliers have been rocked by Trump’s trade tariffs, the MD of Whitebirk Sink Company has refused to change course. Instead, he insists that not only is America still the most lucrative market for the firm’s handcrafted fireclay sinks and basins, but that US contractors will happily cover the new 10% duty.

“We’ve been lucky; the tariff is paid for by the American contractors,” he says. “The only effect on us could be if we became too expensive, but I don’t think 10% on some of the projects we’re involved with is too much of an issue. It’s more about the quality of product with the Americans and they love the ‘Made In England’ label. People like DeVOL are realising that too.”

Allen makes no secret of his plans to drive further growth via the US market and says the currency advantage is really paying off: “A Whitebirk sink in the UK costs £800-£900,” he explains. “In America they’re more like $2,500.”

Part of Darwen Terracotta, Whitebirk was launched by Allen and business partner Jon Wilson back in 2015. The move came after they were made redundant by Shaws of Darwen when Illinois-based Fortune Brands Innovations bought the company and created the House of Rohl, which includes Aqualisa, Perrin & Rowe and Victoria + Albert.

Based in Blackburn, there are 2 strands to Darwen Terracotta – architectural products, managed by Wilson, and the Whitebirk Sink Company. Its factory isn’t far from Shaw’s former site in Darwen where the pair worked together for decades. But while Shaws has recently moved to a modern facility in Wolverhampton, Allen insists that Whitebirk will continue to market itself on old-school artisan craftsmanship, but inevitably on a smaller scale to Shaws.

Now boasting 52 members of staff, Darwen Terracotta was initially funded through a £1.2m loan after Allen and Wilson presented their business plan to private London investors. The pair then set about reemploying many of the skilled craftsmen from the original Shaws team who Allen says had “been left on the scrap heap”.

All the firm’s debts are now paid off and turnover has grown to £7m. Aside from the US market, Whitebirk’s ‘Made In England’ badge is also very popular in Germany, Sweden, Switzerland, and even Australia.

Darwen Terracotta is currently involved in numerous US projects including the Martinique Hotel in New York, while back home it has supplied products to Harrods, the Natural History Museum and various top London hotels. It has also just walked away with both the Made in Lancashire and Export gongs at the 2025 Red Rose Awards, which celebrate the county’s top businesses.

Rather than driving UK growth through an independent retail network, Whitebirk tends to manufacture products for high-end brands like Thomas Crapper as own label. However, it does also sell products directly to retail and through its own website: “We have distributors but that tends to be own-label and we target top-end kitchen suppliers such as Tom Howley,” Allen says. “But now that we’ve entered America we don’t want to take too many distributors on. It’s a niche product and we pride ourselves on customer service and availability. Having too many distributors would overwhelm us. It’s a question of keeping control and keeping your reputation. We’re also reluctant to give the product to the bigger internet guys because we don’t want the price to be destroyed and the independent showrooms to get upset.”

Allen is also keen to introduce points of difference to the product ranges: “Coloured basins are catching on in bathrooms,” he says. “We’ve launched a popular bathroom range under the branding Kréte. We’re also looking at introducing texture to ceramic kitchen sinks. We’ll be launching that at KBB next year.

“The Kréte range is different and people were all over it when we exhibited at KBB last year. We’ve also just displayed Kréte at KBIS in Las Vegas and the attention was far more than for the kitchen range, in fact it detracted from it. Everybody knows what a kitchen sink looks like now and that’s why we’re so keen on product development. Our branding has got to stand out.”

As a top-end brand, Whitebirk is largely protected from the challenging wider picture but Allen suggests prices may soon have to increase “The rich are getting richer as the poor get poorer,” is how he sums the market up. “We haven’t increased prices recently, but it’s something we’re looking at. That will cover energy costs. Making ceramics is high energy use.”

So what’s the plan for Darwen Terractotta and the Whitebirk brand from here? And how long might the pair continue running the business before handing on the baton?

“Eventually we’ll have a new facility, but we’ll never go down the path of robots and modern manufacturing techniques like pressure casting,” Allen concludes. “We’ve spent 10 years building the business up and we don’t want to let go of it. I’m 66 and Jon will soon be 70, so in effect you’ve got old age pensioners running the business. But we have a great young team around us and we’ll go on for as long as we can. We have no plans to sell the business either. If someone came along with an offer we’d be very reluctant to accept it.”

Tags: interview, features, steve allen, whitebirk sink company, sinks, ceramic sinks, jon wilson