Stamford-based bespoke furniture business Bakehouse Kitchens has begun selling its ranges to other independent retailers and is now eyeing the US market for further growth – owner Alan Ramm talks to Tim Wallace.

While the combined impact of Brexit and Covid has crippled many businesses, for Bakehouse Kitchens it triggered a highly successful change in strategy. Before then, the Stamford-based bespoke furniture specialist had been buying in product from German brand Rotpunkt and former Tamworth-based supplier Prentice. But when Covid created a bottleneck in the supply chain it became clear that only by launching its own factory could it secure its future.

Formed in 2008, Bakehouse now makes almost everything it sells and boasts a 14-strong team of bench joiners, designers and installers. The move has paid off, allowing it to keep a tight grip on costs while offering flexible pricing and a guarantee on quality and availability.

Traditional and contemporary kitchen styles can both be catered for and the firm still occasionally uses Rotpunkt for simpler projects. But its overriding philosophy is that to control design it also needs to control manufacture, which allows it to push the boundaries and stay ahead of its competitors.

The company also has ambitious growth plans and, perhaps surprisingly for a showroom based in a sleepy Lincolnshire backwater, a client list featuring what owner Alan Ramm describes as “Kardashian-level celebrities”.

“I can’t divulge who they are but we’re talking huge,” he laughs. “Since we did them it’s just snowballed. We recently did male model David Gandy’s kitchen and there have been a number of celebs we’ve done since. We’re finding this little niche. When people want something individual, which everyone does, I know we can do it.”

Bakehouse has completed work across the UK including prestigious projects in Notting Hill and Mayfair and has also just begun exporting to the US: “These are exciting times,” Ramm says. “I’ve always had a passion for the States; they appreciate things on a craft scale. But we’re excited about the growth in the UK too, there’s plenty of that.

“We’re speeding up our processes so we can take less on but refine what we do,” he adds. “We’re hoping for £3m turnover this year and edging towards 15% growth every year.”

While the main focus is kitchens, around 20% of the Bakehouse business is focused on other areas of the house including bedroom wardrobes, libraries, once even a timbered gymnasium. “It’s low hanging fruit really,” Ramm explains. “It’s easy winnings. We’re playing with all these innovative ideas and setting tomorrow’s trends.”

These are early days for the US venture and Ramm admits he’s proceeding with caution. His first ever shipment was on its way to California on the day of our chat. However, he’s keen to develop this strand of the business which he confides “could be life changing”.

The idea came about after a US interior designer introduced Ramm to a client that loved one of his kitchens. With UK manufacturers like Plain English and Daval already setting a trend out there it seemed an ideal time to get involved.

“We’ve worked in Paris and Italy and we’d looked at shipping to the US for another client so things were in place,” Ramm explains. “We’ve got a second and potentially a third order out there already, but I’m not taking any money on those until I know our hardwood product has arrived without any problems.”

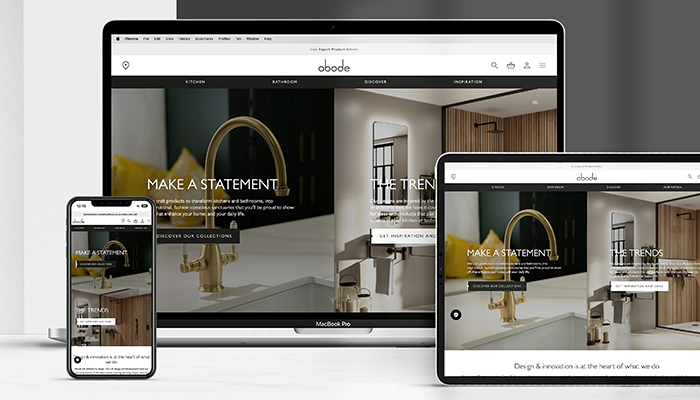

Bakehouse has also begun supplying furniture to other independent retailers. “We have 2 arms to it,” Ramm says. “We manufacture on volume but also do the hardwood products. Then we bring them together as a Bakehouse product or we just sell the cabinets, but some retailers are wanting to buy collaboratively. They’re even happy to buy a Bakehouse kitchen and sell it out of their own showroom so it’s almost becoming a bit of brand for us.”

The company has just achieved what Ramm says is a personal best – a £300,000 kitchen – although he quickly stresses that the firm can also cater for more modest budgets. Kitchens cost an average of £45,000-50,000 and the firm looks for a profit margin of around 10%.

“We always find the budget,” Ramm says. “We work backwards to a lot of other people. We ask the client not to tell us their spend. We do 3 different cost options and ask them what direction they want to go. We can offer MDF or MFC kitchens from £25,000 to hardwood projects of up £80,000. In terms of deposit, we ask for 30% on commission, 60% on delivery and the final 10% on completion.”

So what are the most popular trends right now? And how does the firm differentiate its offer when Ramm admits slick operations like Wren and Howdens are “bridging the gap”.

“We’ve got this wave of real woods coming back,” Ramm says. “The giants have tapped into the lacquers and smooth finished doors so we’re having to move into a sector that can’t be scaled and that’s going to be the stained woods.

“So real woods, using Rubio and Osmo stains are going be absolutely huge,” he says. “We also did reeded panels on David Gandy’s kitchen. Everybody wants some texture now, and to know where their kitchen is coming from and what materials are being used. We look at all sorts; we even made a full prototype of a kitchen made from bamboo, just to show what can be achieved from a smooth painted Shaker in-frame. You’ve got to be different and it’s going to be more and more difficult to be what I call an agent designer where you’re buying in other people’s product. It's becoming a fashionable, iconic industry, almost quite sexy now. It’s getting stronger and stronger.”