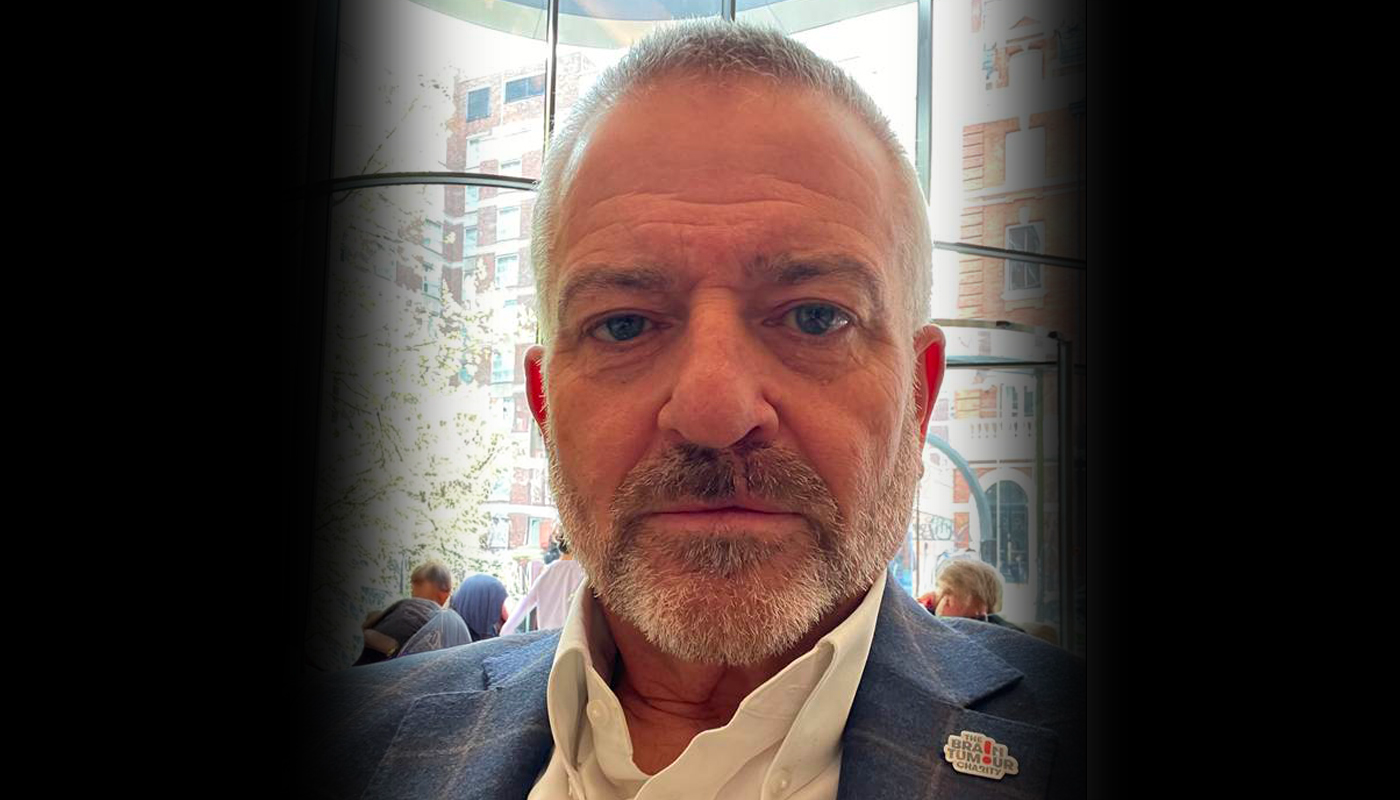

Interview: 'We do fewer kitchens for a lot more,' says Darren Taylor

Thu 9th Dec 2021 by Tim Wallace

Interview: 'We do fewer kitchens for a lot more,' says Darren Taylor

Hampshire-based retailer Searle & Taylor has added £10,000 to its average order value in the last year. MD Darren Taylor talks to Tim Wallace about the net profit that a showroom needs to be successful and gives his top tips on managing lead times.

There’s cause for a double celebration at Searle & Taylor this year. Not only is the kitchen retailer toasting 30 years in business but owner Darren Taylor has just bought the freehold for the showroom in central Winchester.

“This means I can stabilise the business and be here as long as I want,” he says. “We cover the basement, street level and first floor but I’ve now got two more floors to think about.”

That said, the news is unlikely to trigger major expansion plans: “Having more displays doesn’t necessarily mean more turnover and more profit,” he explains. “I’m a control freak and I love that we just do four kitchens a month, and we can control them, do them really well and make a bit of money.”

Taylor launched the firm when he was only 18 and has used his experience since then to develop a strategy based on careful forward planning and a slow shift into the luxury end of the market.

“We do less for a lot more now,” he says. “And interestingly, our average order value last year was up by £10,000. Turnover went down but so did our costs. So we were actually still profitable.”

The company sits between a turnover of £1.2m and £1.6m, but the average order value is now £47,000 excluding installation and hand painting.

“A good retailer should be making between 35-40% gross profit, leaving a net profit of hopefully 10%,” Taylor suggests. “Plenty will start at 40% but your gross profit will always drop, something will attack it. So start off at 38-40%, finish at 35% and you’ve got yourself a good business.”

Searle & Taylor has found success in offering Austrian furniture from Ewe and Intuo rather than the German brands favoured by many of its competitors. A bespoke handmade range is also part of the mix.

“I’ve just had a meeting with Ewe and they’re extremely busy,” he says. “But their lead time is now 12-13 weeks which is four weeks longer than it should be.

“So there are negatives but that’s come off the back of a huge upsurge in orders. De Kreis says this boom period will continue for a couple more years. We’ll have supplier issues into next year but hopefully things will start to come good from April. It’s all about managing it – if you know your lead times are going to be 10-12 weeks you can even use it as a bit of a closer. Tell your client you need the order now so their appliances come in time.”

Current design trends include boot rooms, utilities, walk-in pantries and studies. “But the newest one, which I love, is bootility,” he laughs. “It’s a crossover with a boot room and a utility.”

Taylor also used the time during lockdown to produce a new brochure and admits the reaction was unexpected.

“Our approach initially was a digital download but we’re getting 30 odd requests a month and 80% of them are for the print version. That was a huge surprise. The brochure is about us and our approach to design. It’s been like gold dust. We monitor the planning applications locally and send it out to anyone doing a kitchen project.”

But with the pandemic lingering on, and inflation on the rise, how optimistic is he for the year ahead?

“Everyone is panicking but we’re only seeing fairly normal price increases of 3-4%,” he says. “Most appliance companies are embarrassed about their long lead times and the problems they’re getting finding chips. But next year we’re going to see interest rates rise and some price increases.

“My tip is to make quotations only valid for 21 days. If you let a quote go on longer than that your costs can start going up very quickly.”

Tags: interview, features, darren taylor, searle & taylor, kitchens