Aimee Fletcher – How to value engineer your projects with Egger UK

Aimee Fletcher – How to value engineer your projects with Egger UK

Aimee Fletcher, Egger UK’s design & product manager, shares how making simple swaps from real materials to Egger’s market leading reproductions can reduce cost, save time and increase environmental credentials.

Whether it is budget control, time constraints or compliance with environmental frameworks, there are simple, accessible solutions in the market to help value engineer even the most complex of projects.

In an economic climate of rising prices and lower consumer spending, cost becomes a vital consideration when it comes to design, and significant savings can be made by looking at alternatives to authentic materials such as stone, metal or wood veneer. These not only carry a significantly higher price tag, but often require specialist fabrication or recurring maintenance, adding to cost pressures. By making simple swaps to alternative materials, such as laminate worktops or decorative faced chipboards, you can not only control the budget at source, but also over time.

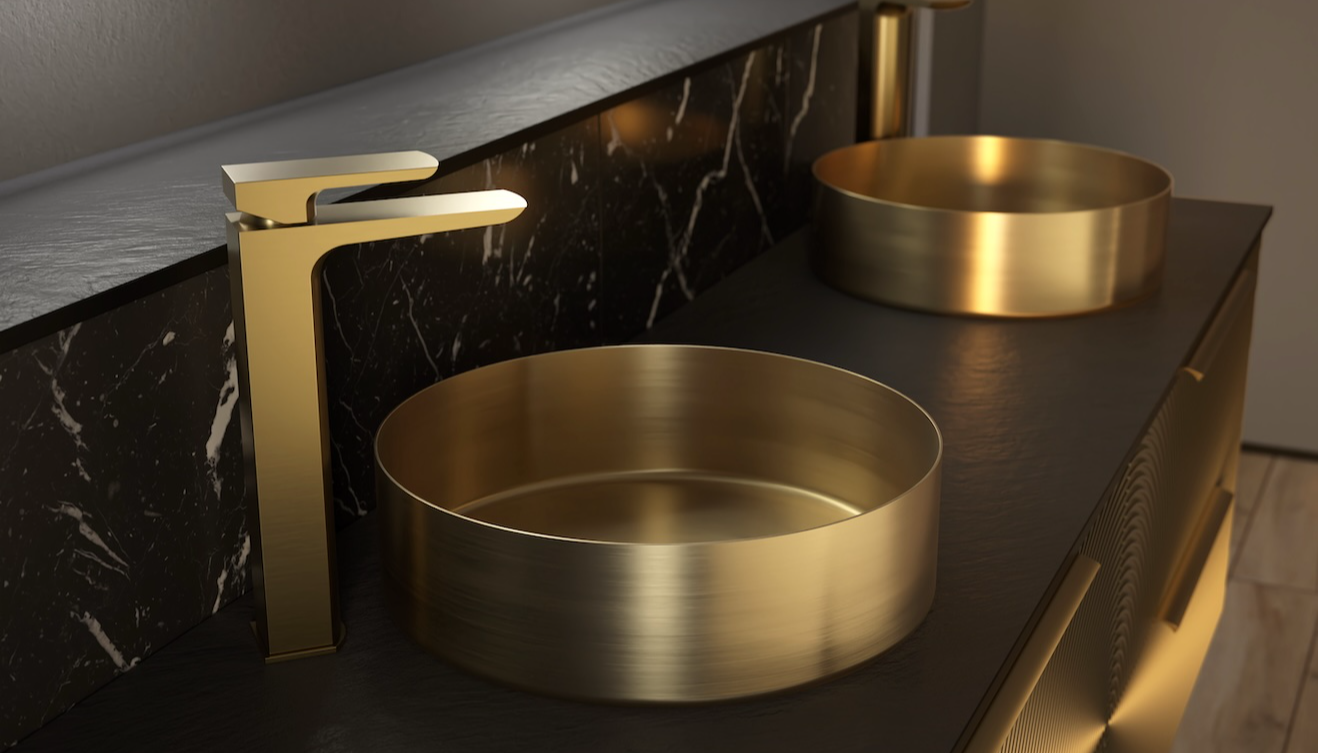

Let’s take natural stone for example, which is trending in high-end design. With factors such as weight, handling and waste to consider, fabrication and fitting can notably impact a budget. Additional costs can occur over time with recurring treatment such as sealing. When you are looking to avoid mounting costs, the benefits of wood-based reproductions should not be overlooked. With features such as scratch and stain resistance, lightfastness and stability, these products are also simple and efficient to install and require no ongoing maintenance. Cost differences can be significant, with natural stone countertops often amounting to 1100% more expensive than a laminate reproduction.

Time is also a key factor in any project schedule, and choosing materials that demand additional processing or ongoing labour can significantly delay completion. Stay on track by choosing alternative products in versatile formats, that offer fast and efficient processing, reduce waste, and are readily available in pack sizes optimised to streamline fabrication.

Take painting wood or veneer, for example, which may require multiple processes and substantial labour hours. By considering reproduction materials that offer the same look in a ready made finish, your projects can be streamlined and remain on course for a prompt delivery. In case of damage during fabrication, replacements can also be sourced at pace and without disruption to the schedule. Remember to consider this additional labour on the scale of your project. In a multi-unit development, even a small amount of extra labour per install could be the difference between a prompt or delayed delivery.

Making savings on costs and time are not the only way to add value to a project. Minimising environmental impact, and increasing sustainability credentials, adds another level of worth to a project that is of growing importance in the furniture and interiors sector. Look for products that make use of recycled content and are recyclable at end of life, promoting material circularity. Manufacturers’ raw material procurement and production techniques should also be considered, and attention paid to supporting documentation available via websites and published resources.

Remember, natural does not necessarily mean sustainable. Many naturally derived materials, such as stone, marble or metal, require energy extensive processes, and carry substantially higher carbon footprints as a result of fabrication and transportation. Non-recyclability is often another factor.

Overall, product performance and design integrity are always top priorities, but there is no need to over specify. By selecting the right material technology for specific application areas, and choosing carefully developed finishes with high quality prints and textures, you can ensure a product’s specification is fit for purpose, with added value and without compromise on design.

Whether you are looking to make simple swaps from natural stone worktops, ceramic floor tiles, metallic facades or wood veneered doors, there are alternative products readily available that cost less, save time and keep environmental impact at a minimum. By choosing reproductions, your projects will become more affordable, delivered more efficiently, and very likely to achieve your environmental targets.

Tags: insight, features, aimee fletcher, egger, laminate, kitchens